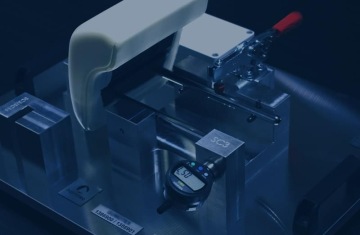

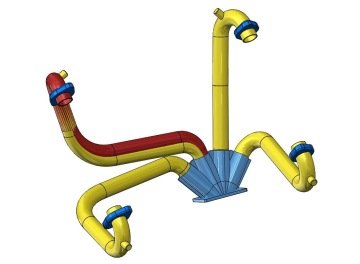

Pipe and tube bending

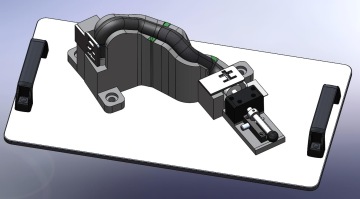

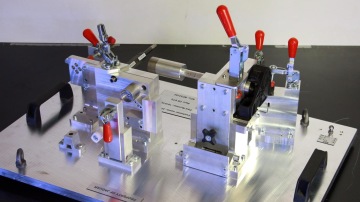

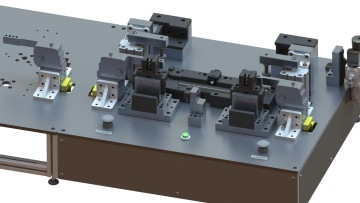

Assembly, checking and measuring fixtures by HolmTec

The company has been operating since 2005, in the engineering and automotive industries. We mainly deal with the introduction of automation and robotics into production processes, development, modernization and production of single-purpose machines, fixtures with established POKA-YOKE principles. Last but not least, we also deal with the bending of tubes, pipes, bars and rods.

The main offer of our services

Pipe and tube bending

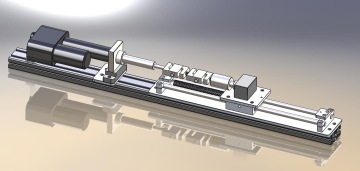

Bending of thin-walled and thick-walled pipes is carried out by the so-called cold forming method, on CNC and NC machines.

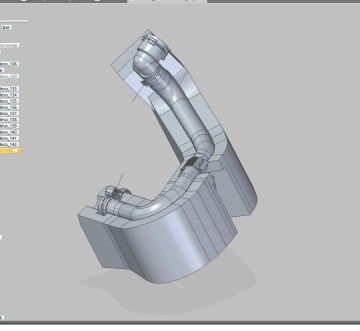

Tube bending technology enables smooth bending in 3D space according to the specified XYZ coordinates or according to the 3D model...

Production CMJ

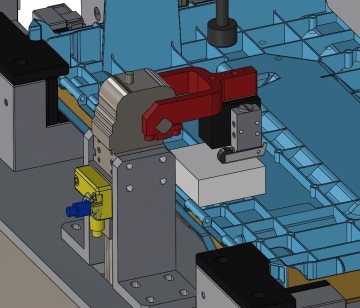

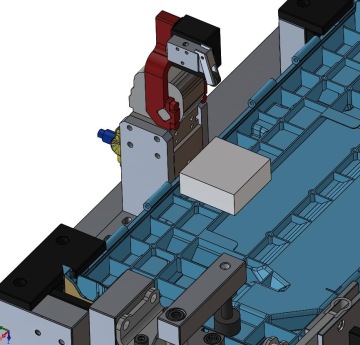

Control devices are used for intermediate and final control of the shape, dimensions, positions, mounting points and completeness of assemblies. By using and using the products, possible deviations are eliminated or completely minimized...

Design / Development

We offer our customers long-term experience in the field of design and production of control tools. Ensuring error-free output or inter-operation control in a fast and efficient way is the main goal of every production process...

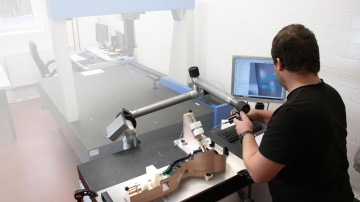

Department of Metrology

We measure on a Faro 3D measuring arm or coordinate CMM measuring machine. It is common to measure and compare the 3d model with real parts.

We measure small parts in inter-operation checks, but also larger parts or assemblies...

Production cooperation in the Czech Republic

what does it consist of

Cooperation in the field of production and assembly

Design - Innovation - Machine production

Pneumatic components and machines - Festo -Pneumax

Assembly of the products

Welding of stainless steel and aluminum

Design and assembly of aluminum profile systems - Item

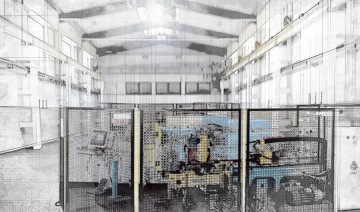

Automation

Lean production

Karakuri

Partner in application to production processes

Increasing the speed of production

Elimination of manual measurement

Zero error and incorrect assembly avoidment

POKA-YOKE principles

Increased work safety

Acceleration of quality control

Advantages of cooperation with us

Qualified expertise

Tradition of engineering

Individual approach

More than 16 years of experience in automotive

Average salary from 1533 EUR/month

Now Free Capacity

Short delivery times

Your benefits

CAD / CAM design office

We focus on:

welding fixtures - clamping fixtures - positioning and assembly fixtures - measuring fixtures - single-purpose machines - 3D printing of prototype parts

-

We will process a 3D model of the construction design.

-

We have rich experience with foreign drawings.

-

When designing, we will take into account our experience with the given issue.

-

We base all orders for the production of preparations and some other products that we manufacture with our own design.

We will give your thoughts and ideas a real shape.

Principles of POKA-YOKE

Error elimination, better quality, lower costs, increased operator safety, lower operator skill requirements, increased production flexibility, better operator access, simplification and better maintenance

Technique principles of Poka - Yoke

they are one of the most important methods of quality management and improvement of production processes. We apply the principles of Poka Yoke in the construction of inspection templates, clamping jigs, measuring jigs, but also on assembly tables.

By introducing these principles into production, the primary goal is to reduce production defects, then to reduce production costs, mainly due to the minimization of errors. Increased safety and reduced risk of accidents at work and production flow is optimized.

Take advantage of cooperation with high expertise and production productivity.

Machine innovation and construction.

B2B Czech Republic is the Way to reduce costs.

Are you still not using qualified production cooperation with the Czech Republic?

News

Podporujeme: CTU CarTech - Formula Student Team

Těší nás, že jsme se mohli podílet na svět zajímavému projektu - CTU CarTech.

Oznámení: COVID-19

V souvislosti s vyhlášením mimořádné situace v České republice bychom vás chtěli ujistit, že jsme přijali opatření k zajištění,...