Aluminum profiles and modular systems

Design and Development

Custom production

The industry is constantly evolving and becoming more demanding and faster

The demand for innovative and efficient solutions for the construction of machines and production lines is growing. In this context, aluminum profile systems, often referred to as ALU profiles - Aluminum profiles - Aluminum profiles, play a key role. These lightweight and modular profiles offer a number of advantages over traditional welded steel structures. This article focuses on the design, construction, construction, use and utilization of ALU profiles in the manufacturing industry.

I. Design and construction of ALU Profiles

ALU profiles are made of high-quality aluminum and have a special shape geometry that provides them with high strength and stability. These profiles are available in different sizes, shapes and lengths, which allows them to be easily connected and create complex structures. Structural systems of ALU profiles are designed to provide maximum flexibility and easy modification of the structure during the entire life cycle of the device.

II. Construction and usage

Construction using ALU profiles is fast and simple thanks to the modular design. The parts are easily connected using special fasteners, which minimizes assembly time and costs. The construction process is also clean as there is no need for welding, which reduces the risk of emissions and fires. ALU profiles are also lighter than steel structures, which allows for easier handling and assembly. At the same time, this reduces the demands on handling equipment and increases the ergonomics of the assemblers' work.

III. Use of ALU Profiles in the Industry

ALU profiles have a wide range of uses in the manufacturing industry, especially in the field of machine and production line construction. Some of the major applications include:

Production lines:

ALU profiles serve as basic building blocks for the assembly of production lines, where flexibility and easy modification depending on production requirements is needed.

Assembly workplace:

Construction using ALU profiles provides the ideal basis for ergonomic assembly workplaces that maximize operator efficiency and comfort.

Conveyor systems:

ALU profiles are used for the production of light and durable conveyor systems for handling materials.

Protective barriers and railings:

The advantages of lightness and easy joining make ALU profiles an ideal choice for protective barriers and railings around machines and work surfaces.

Frame construction:

ALU profiles are used for the production of machine frame structures that require higher strength and durability.

IV. Advantages of ALU Profiles compared to welded steel structures

- Weight: ALU profiles are lighter than welded steel structures, which allows for easier handling and assembly.

- Assembly speed: Thanks to the modular design and simple joining, ALU profiles are assembled faster, which saves time and labor costs.

- Flexibility: The possibility of easy adjustment and modification of the structure when requirements change or production lines are expanded.

- Corrosion resistance: Aluminum has a natural resistance to corrosion, which extends the life of the structure.

- Cleanliness and safety: Without welding, the risk of fires and emissions of harmful substances is minimized, which contributes to the improvement of the working environment.

- Aesthetics: ALU profiles offer a modern and attractive appearance, which can be important for the presentation of a company's image.

The industry is increasingly interested in innovative solutions that provide an efficient, flexible, and safe environment for machine and production line construction

The main advantages of working with us

ALU profiles bring key benefits

-

lightness

-

modular design

-

quick assembly

-

corrosion resistance

These properties make them an ideal choice for modern industrial applications that seek to achieve higher productivity and competitiveness.

We use ALU profiles in the creation of sophisticated workplaces for measurement, inspection, assembly and other industrial applications, which bring a number of concrete advantages.

How can ALU profiles contribute to the efficiency and optimization of these workplaces?

Assembly workplace for the production of electronics

ALU profiles are used to create ergonomic assembly stations for the assembly of printed circuit boards (PCB) and electronic components. Thanks to the modular design, the workplace can be easily adapted to the requirements of the given production. Special accessories such as shelves, tool holders and LED lighting improve operator accuracy and comfort.

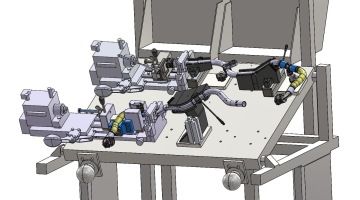

Special construction for the production of prototypes

New product development often requires rapid design and assembly of prototypes. Thanks to the easy adjustment and modification of the structure, ALU profiles are the ideal solution for the creation of prototype workplaces.

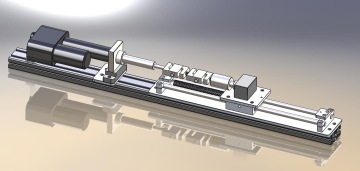

Conveyor systems for assembly andmeasurement

ALU profiles are the basis of light and precise conveyor systems that enable precise handling of products during their measurement, inspection or assembly. Shape variants of the profiles can be used for easy guidance of products along the conveyor.

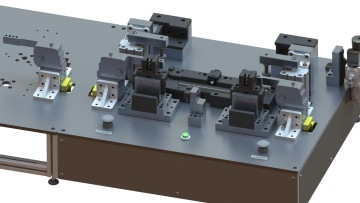

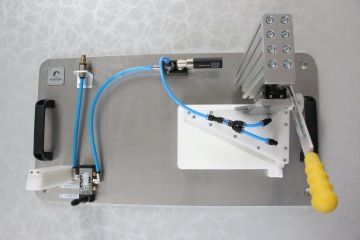

Checking station

Test stands and stations

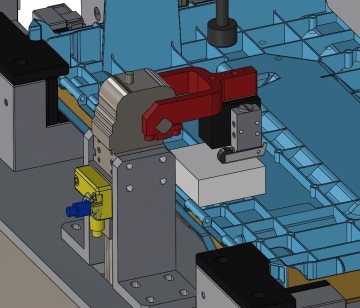

Workplace for robotic systems

ALU profiles are used to create a stable and solid frame for control stations and inspection desks. The flexibility of the ALU profile system allows the easy addition of measuring devices, monitors and other components that are necessary for product quality control

A stable and solid foundation is needed for testing various industrial components. ALU profiles allow easy creation of customizable test stands with different configurations. This allows quick change between different test procedures.

New product development often requires rapid design and assembly of prototypes. Thanks to the easy adjustment and modification of the structure, ALU profiles are the ideal solution for the creation of prototype workplaces.