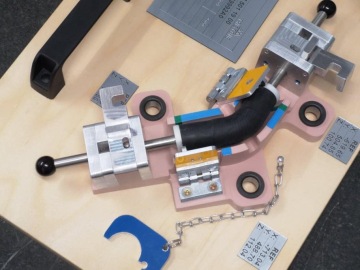

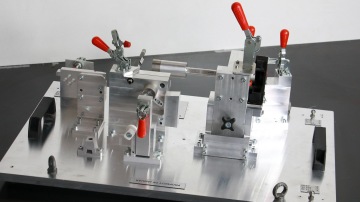

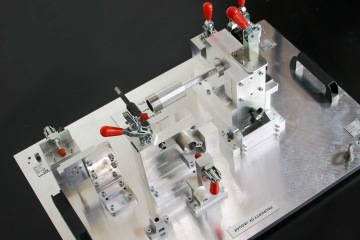

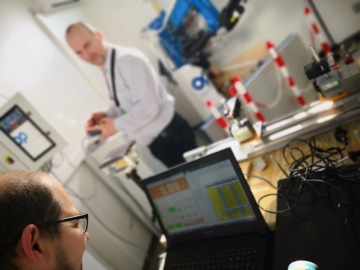

Checking fixtures and workplaces

Development, design and manufacturing

of checkingfixtures

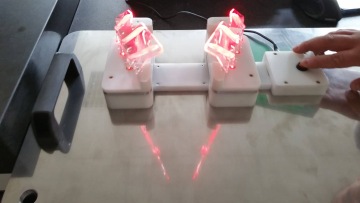

Fast and accurate inspection of parts during production processes

For thorough control in production processes.

-

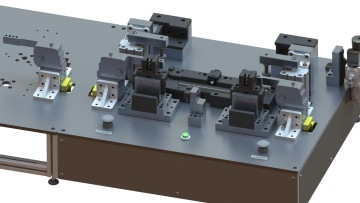

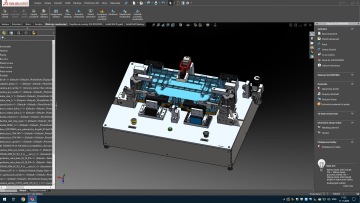

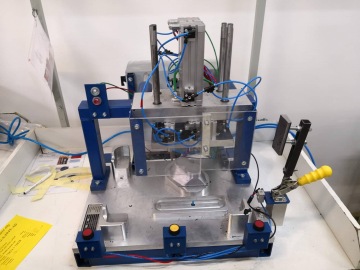

As part of development and production, checkingfixtures are individually designed with regard to the optimal solution and the customer's own requirements.

-

For more complex designs, documentation containing instructions for use and the methodology for checking parts is included.

-

The checking fixtures fully meet all the requirements of the relevant standards.

Checking fixtures or checking machines, are designed:

Commonly used materials for the production of fixtures

Aluminium

Stainless steel

Steel

Sikablock

Wood