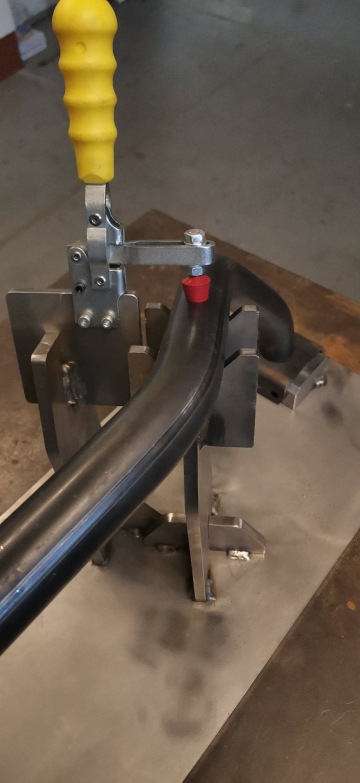

Welding fixtures

Development, design and manufacturing

of welding fixtures

Welding fixtures

for manual, automated and robotic workplaces, they are primarily intended for fixing welded parts.

The welding fixtures ensure

Applying the Poka-Yoke system results in a flawless welding process. It can partially serve as a control and assembly tool. Exact fitting when assembling parts, exact fitting of components, checking positions, checking shape and size.

Welding fixtures and jigs are designed:

Commonly used materials for the production of the fixtures

Stainless steel

Steel

Sikablock

Subsequent output inspection and 3D measurements

The welding fixtures are checked and subsequently measured on CMM and the FARO measuring arm. All welding fixtures are supplied with a measuring protocol.

For more complex designs, documentation containing instructions for use and methodology for welding parts is included.

The welding fixtures fully meet all the requirements of the relevant standards. In the framework of development and production, welding fixtures are individually designed with regard to the optimal solution and the customer's own requirements.

Measuring equipment

- FARO - portable 3D measuring arm

- Werth ScopeCheck® 400 - Multi-sensor coordinate measuring machine for high-performance measurements

- CMM - Poli Sky7 - coordinate measuring machine. The POLI CNC system is a fully automatic system driven by the most up-to-date personal computer.